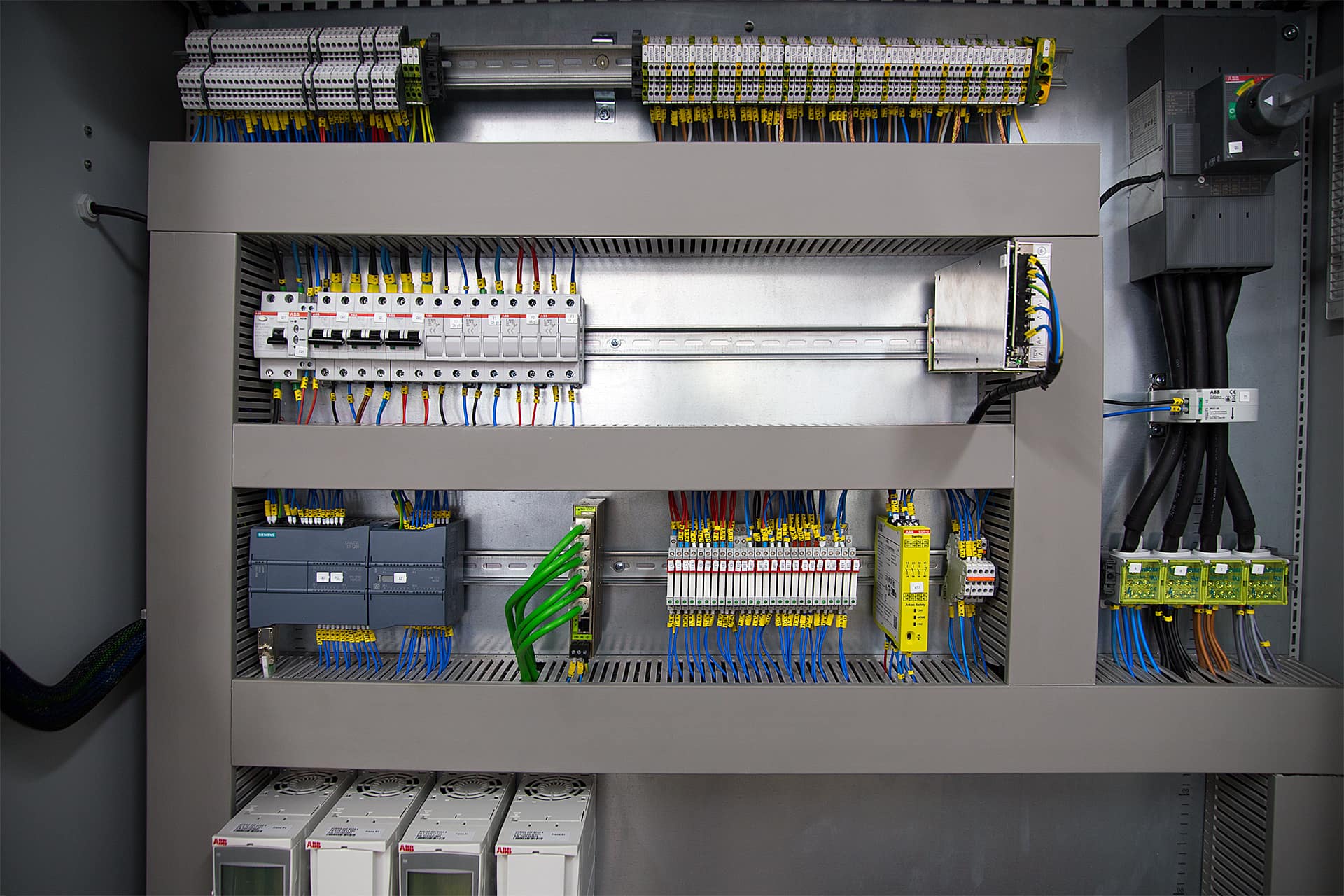

An industrial electrical panel is, basically, an electrical cabinet in charge of managing the current of each of the components of an installation. A centralizing element where all the wiring comes together and from which we can control the adequate power of each device.

The type of electrical panels that we currently manufacture in MG Electricidad are those intended for companies, generally factories, called industrial process control panels.

Specialists in customized electrical panels

For more than 40 years, MG Electricidad has been dedicated to the design, manufacture, assembly and maintenance of customized industrial electrical panels. There are different models and sizes, which vary depending on the need, location and structure of each factory or production line.

Electrical panelboards are a key element in any industrial installation. Their function is crucial to control the electrical power and protect the wiring circuits that supply energy to the whole plant.

In addition to the maximum guarantee, we take care of upgrading and fine-tuning your customized electrical panel. Equipped with the latest technology, risks will be avoided and we will be able to optimize the energy efficiency of an installation to the maximum.

Industrial electrical panelboards play a vital role in companies. On the one hand, to reduce the risk of overloads to a minimum and, on the other hand, to prevent short circuits in the installations as far as possible. As a result, such protection is able to prevent electrical fires or high voltage surges, which could damage machinery. On the other hand, it optimizes costs and increases the speed of production lines.

What is an industrial electrical panel

Request a quote

Industrial electrical panel functions

Installation safety

It prevents overloads or short circuits, i.e., prevents against possible fires. In case of danger or spark, the panel cuts off the power.

Wiring layout and order

As a container for various electronic material, it protects the circuits of the installation, leaving the entire wiring structure tidy and neat.

Electrical power control

Management of the adequate energy power of each element connected to the electrical network.

Production supervision

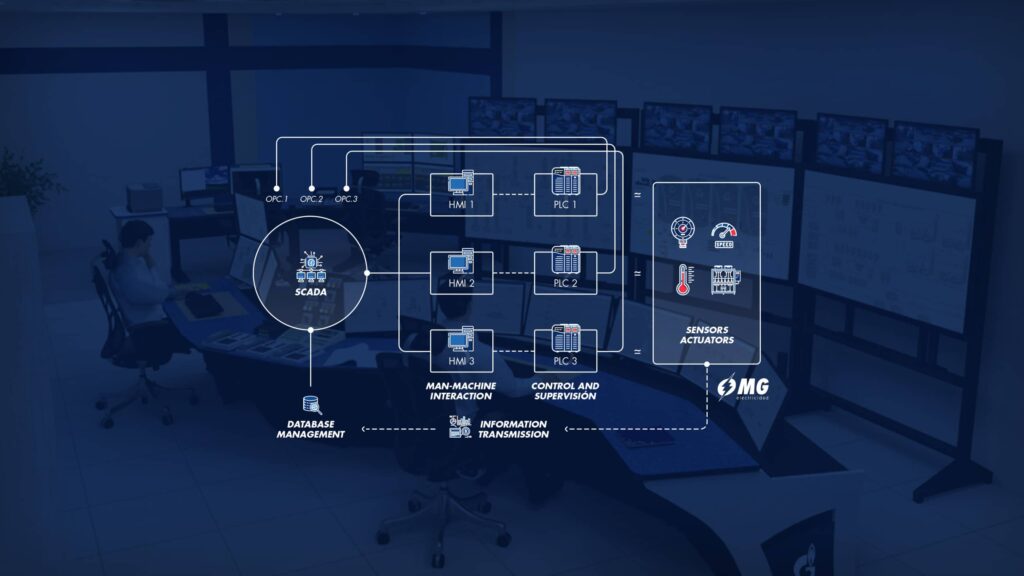

The control panel software checks the functioning of the equipment that make up the production line.

Remote technical service

It allows to carry out relative manoeuvres to the devices that make up the same industrial process.

Benefits of a customized electrical panel

Business benefits of having an updated electrical cabinet:

- Modernization and increased company value.

- Increased factory productivity.

- Optimization of electricity consumption.

- Savings in maintenance costs.

- Reduction of occupational risks, due to electrical accidents.

- Elimination of outages between work shifts.

- Scalability and greater efficiency.

- Adaptation of the industrial installation to the current regulations.

Manufacturing process of our custom-made electrical panels

In MG Electricidad we are able to undertake the complete process of design and manufacture of a custom electrical panel. The following are the basic steps that make up the development of each project:

1. Study of the installation

Preliminary study of the installation by our technicians. After analyzing the documentation provided by the customer, we offer a study, in order to provide the best solution, based on your electrical installation.

Revised documentation is essential to avoid future budget mismatches.

- Estimate prior to installation.

- Calculations on the electrical installation.

- Estimation of production optimization.

- Panel or project design.

2. Design of industrial electrical panels

Once the electrical installation planning has been prepared, we proceed to design the electrical panels in Eplan, and draft all the necessary documentation for the next step, their manufacture. This data will be provided to the customer in a PDF file.

In addition to years in the industry, we are up-to-date with the latest technologies, and specialized in the design of electrical panels.

3. Electrical panel manufacturing

The manufacture of the electrical panel is always carried out according to the technical report created by our electrical engineering team and previously approved by our customer. MG Electricidad‘s technical office establishes the guidelines to be followed, the necessary cable sections, etc.

Our technician assigned to the installation will be responsible for reviewing each assembly step of the electrical panelboard.

4. Tests and trials in simulation mode

To achieve the highest quality in your electrical installation, from MG Electricidad we perform a series of tests, called control protocols. Through a checklist, we check point by point, to comply with the requirements according to the regulations of the country of destination.

In addition, as required, we can establish complementary studies.

5. Documentation according to plan

After performing the FAT (Factory Acceptance Test), we generate the official As-Built documentation of your project. We implement the modifications already approved in the documentation. These data are physically incorporated inside the electrical panel itself, as well as provided to the customer in PDF format.

The type of certificate, CE Marking or UL Certification, and its own serial number are also recorded on the inside of the electrical cabinet.

The inside of the electrical panelboard also bears the type of certificate, CE Marking or UL Certification, and its own serial number.

6. Transportation and installation of the electrical panel

From its manufacture in the workshop, through transportation to your factory, to the final installation of the electrical panel. In MG Electricidad we take care of everything. In cases where the customer requires it, we take care of the commissioning and installation. In addition, we offer a maintenance and updating service.

We work nationally and internationally. We offer remote support, or we will come to your facilities, depending on your needs.

Price of an industrial electrical panel

It is a complex and highly variable subject. Many customers often ask us at first what is the average price, or how much can be around an industrial electrical panel. And from MG Electricidad we always give the same answer: “for an electrical panel there is no fixed or standard price“, since each installation has its own complexities and requirements closely linked to the context that encompasses them.

To calculate the price of your industrial electrical panel, our team will need to previously analyze your factory, its production model, technology and consumption, as well as to know the future expectations. Everything related to your installation, to design a custom electrical panel, suitable to your present and scalable over time.

Together with our workshop managers, we will prepare a customized quotation, completely adapted to your needs.